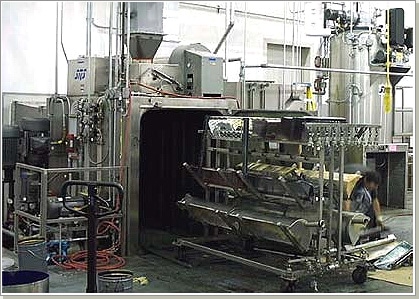

Narrow Web Press Washer (NW-Series) for Pail Washing, Can Washing, Narrow Web Printer Component Washing, Parts Washing

for Pail Washing, Can Washing, Narrow Web Printer Component Washing, Parts Washing

The NW-Series is a washer designed specifically for narrow web printer parts and press wash systems, as well as printer components and fittings. Our NW washer is a totally enclosed stainless steel wash system featuring high impingement jet spray technology for optimal efficiency and versatility. The Narrow Web Press Washer is configured to wash both the inside and outside surfaces of narrow web printer components and a wide range of containers including pails, cans, glass jars and miscellaneous parts. A Programmable Logic Controller (PLC) automatically executes an operator selected WASH, RINSE, PURGE, and optional DRY cycle. Interlocked controls and optional VOC abatement systems make the NW-36 ideally suited for the most demanding industrial applications.

| UNLIMITED APPLICATIONS | TYPES OF CONTAINERS |

|

|

Specifications

-

- Pumps

Pull out basket for optimal versatility - Pressure

- Flow -80-150 psi to 20 gpm

- Cycles -programmable WASH, RINSE, PURGE, and DRY cycles

- Connection -1″ inlet and outlet (water/solvent)

- Power -440 or 220v, 3 phase

- Dimensions -78″W x 48″D x 78″H

- Material of construction -Brushed 304 stainless steel

- Teflon fittings for solvent compatibility

- Pumps

Standard Features and Options

-

- Automatic PLC control

- Digital display for setup, operation status, and fault conditions

- Interlocks for optimal safety

- Electric wash and re-circulating pumps

- Stainless steel construction

- Interior wash

- Color Touch screen display

- Explosion resistant design for Class 1,

Division 1 environments - Rinse / sanitizing cycle

- Drying cycle

- High pressure pump (250 psi)

- Pail / parts wash racks

- External wash tank heating system for aqueous applications

|

High efficiency washing and liquid removal pumping system |

|

|

|